Quality Care with a “C” for Cándido

Facilities in continual improvement

Our facilities in Carbonero el Mayor (Segovia) measure a total of 3,700sqm including:

- Delivery bay for raw materials

- 2,000sqm given over to cleaning, washing and packaging the carrots and leeks

- Hydrocooling system using static and dynamic cold water showers

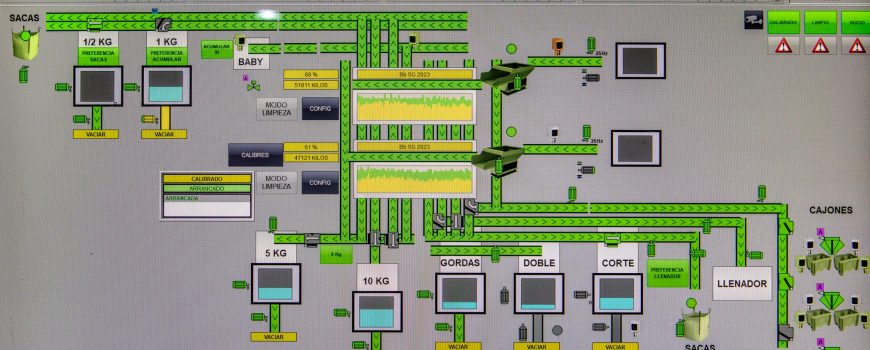

- Optical graders that differentiate and select the carrots automatically

- Digital control of processes and video camera for monitoring

- Two areas with cold storage rooms, one for the raw materials and the other for the finished product

- Robot to match up product palettes

- Purification and recycling system for external water

- Facilities with solar panels on the warehouse roofs

All of this allows us not only to maintain the qualities of the harvested crops, but also facilitates traceability and quality control with the most demanding of standards.